Materials scientists at Harvard use computers at the MGHPCC to design better solid-state lithium ion batteries through advanced characterizations and simulation.

As electric cars have evolved, running costs have begun to approach those for their gasoline forebears – more expensive to buy, cheaper to run – but range and charge time remain an outstanding issue. Leading the list of possible game-changers are solid-state lithium ion batteries in which wet electrolyte is replaced with a solid. Simpler, such units have the potential to be a lot cheaper, lighter, and not require liquid cooling. They are expected to also be longer-lasting and fireproof while potentially being much faster-charging too.

A major impediment to the development of solid‐state lithium‐ion batteries, however, are interfacial reactions between ceramic‐sulfide solid‐electrolytes and common electrodes. Such reactivity means that ceramic‐sulfide batteries require a suitable coating material to isolate the electrolyte from the electrode materials.

Xin Li, a materials scientist at Harvard, is focused on the design of new energy-related materials through advanced characterizations and simulations. By combining electrochemistry, electron microscopy, X-ray diffraction, and first-principles simulations, his team uses Harvard’s Odyssey Cluster (housed at the MGHPCC in Holyoke, MA) to understand the relationship between atomistic structure and electrochemical property of materials.

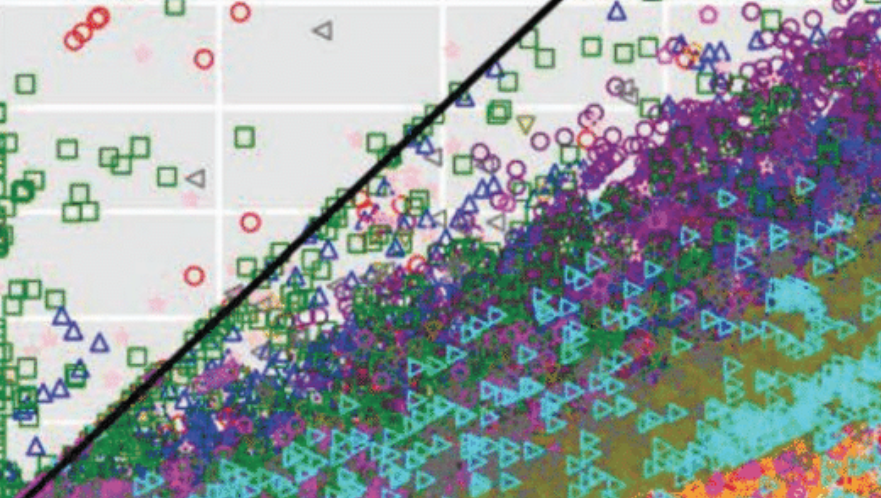

In new work published in the journal Advanced Energy Materials Li, working with graduate student William Fitzhugh and others in Harvard’s Paulson School of Engineering, computationally evaluated the interfacial stability of the lithium sulfide Li10SiP2S12 with over 67 000 potential coating materials. Their study found 2000 materials predicted to form stable interfaces in the cathode voltage range and over 1000 materials for the anode range. Studies like these are invaluable in narrowing the field of potential candidate materials ahead of physical trials.

Systematic assessment through first-principles analysis of large systems like this is of course computationally highly demanding. Innovations introduced in the paper included a new binary‐search algorithm to improve the speed and accuracy for evaluating pseudo and the authors highlight the computational challenges posed by high‐throughput interfacial phase‐diagram calculations as well as pragmatic computational methods they would recommend to make such calculations routinely feasible.

In addition to the over 3000 materials cataloged, representative materials from the anionic classes of oxides, fluorides, and sulfides were also chosen to experimentally demonstrate chemical stability when in contact with Li10SiP2S12. “We chose LiCoO2 as an example cathode material to identify coating compounds that would be stable with both Li10SiP2S12 and a common cathode,” Li explains. “Analyzing the correlation between elemental composition and multiple chemical and electrochemical instability metrics revealed key trends in, amongst others, the role of anion selection.”

Xin says the next step in this work will focus on computationally determining and experimentally realizing the best interface coating material by considering more advanced effects in all-solid-state batteries.

To find out more about this work contact Xin

William Fitzhugh, Fan Wu, Luhan Ye, Wenye Den, Pengfei Qi, Xin Li (2019), A High‐Throughput Search for Functionally Stable Interfaces in Sulfide Solid‐State Lithium Ion Conductors, Advanced Energy Materials, doi: 10.1002/aenm.201900807

The Culprit of Superconductivity in Cuprates, John A. Paulson School of Engineering and Applied Science News, Harvard University